In the modern cable and wire manufacturing industry, the demand for high-precision, durable and efficient product identification is increasingly prominent. Fiber laser marking machines have emerged as a revolutionary solution, transforming the trad...

In the modern cable and wire manufacturing industry, the demand for high-precision, durable and efficient product identification is increasingly prominent. Fiber laser marking machines have emerged as a revolutionary solution, transforming the traditional marking process with their unique technical advantages. This advanced technology has become an indispensable part of the cable production line, providing reliable marking services for various types of cables, including power cables, communication cables and special industrial cables.

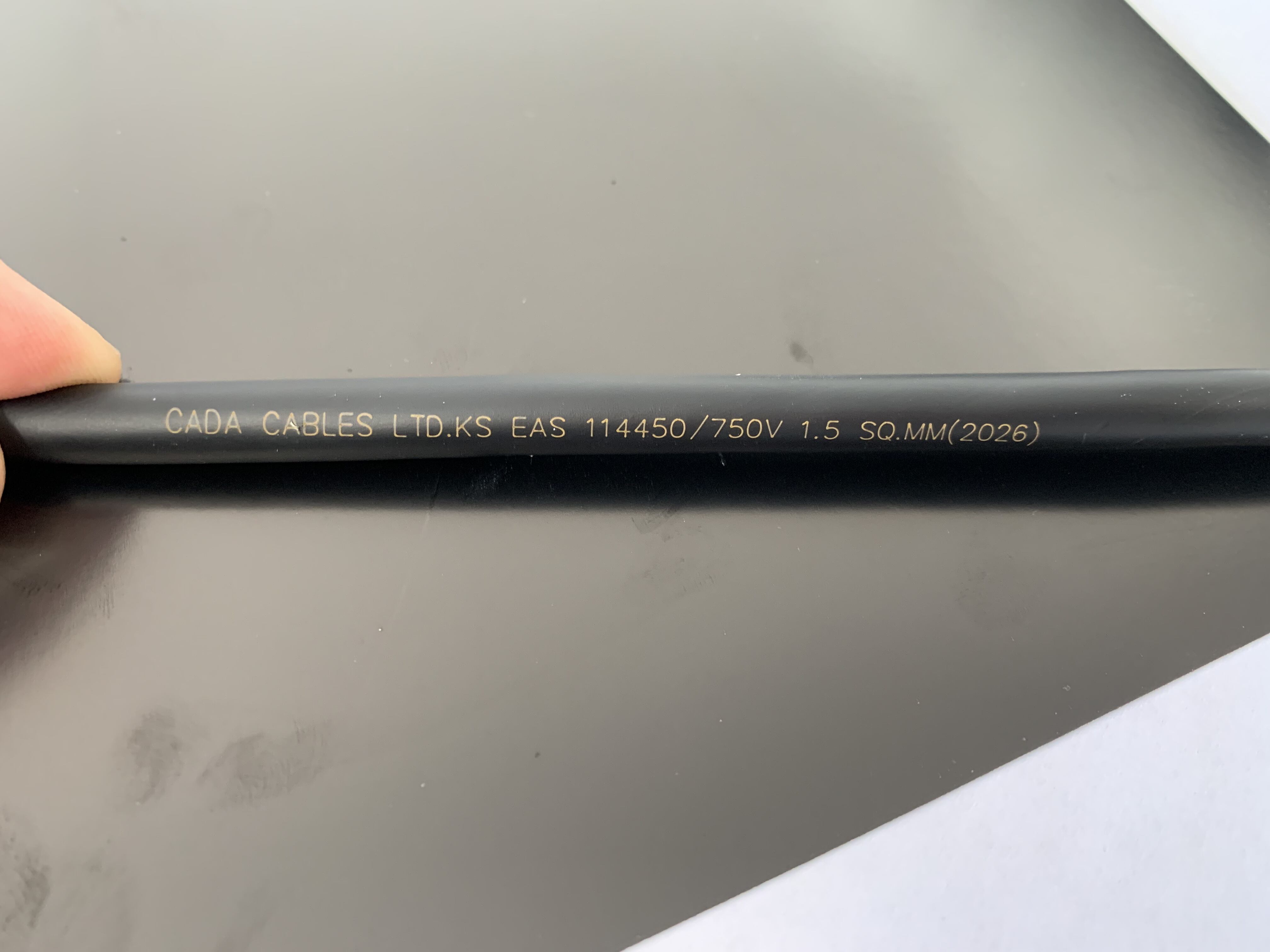

One of the core advantages of fiber laser marking machines lies in their permanent and high-definition marking capabilities. Unlike traditional inkjet printing or labeling methods that are prone to fading, smudging or falling off, fiber lasers create marks by causing microcosmic changes on the cable surface, such as material evaporation or color change. These marks can withstand harsh environmental conditions, including high temperatures, corrosion, friction and chemical exposure, maintaining clarity for over 10 years . With a minimum line width of 0.03mm and minimum character size of 0.15mm, they can easily meet the requirements of printing tiny information such as batch numbers, serial numbers and QR codes .

Efficiency and automation are another major highlight of fiber laser marking machines in cable applications. Equipped with professional online flying marking systems, these machines can realize real-time speed measurement and dynamic marking adjustment, perfectly adapting to high-speed production lines with a maximum speed of up to 600 meters per minute . The advanced control software can intelligently calculate the spacing between marks, overcoming the limitations of marking content length, and supporting 24-hour continuous operation . This automation level not only improves production efficiency by 3-5 times compared with traditional methods but also reduces human errors, ensuring consistent marking quality in mass production .

Environmental protection and cost-effectiveness have made fiber laser marking machines the first choice for green manufacturing. The marking process requires no ink, glue or other consumables, producing no chemical pollutants or hazardous waste . With a laser service life of over 100,000 hours, these machines have extremely low maintenance costs, significantly reducing the long-term operational expenses for manufacturers . In contrast to traditional methods that generate consumable waste, fiber laser marking aligns with the global trend of environmental protection and sustainable production.

The versatility of fiber laser marking machines enables them to adapt to various cable materials, including PVC, PE, ABS, HDPE and even metal conductors . They support 360-degree all-angle marking, easily handling different cable shapes such as round, square and flat cables . The marking content is highly flexible, covering text, dates, logos, vector graphics and machine-readable codes like QR codes and barcodes. The dedicated software is compatible with AutoCAD, CorelDRAW and other design software, allowing for quick content modification without production interruption .

In practical applications, fiber laser marking plays a crucial role in cable traceability and quality management. By marking unique identification codes on each cable, manufacturers can realize full-process tracking from production, transportation to installation, which is in line with the requirements of national standards such as GB/T 38662.2-2023 . For the communication and power industries, these marks help with quick maintenance and fault location, improving service efficiency. In special fields such as aerospace and medical equipment, the high-precision and non-damaging characteristics of fiber laser marking ensure the safety and reliability of special cables .

As the cable industry moves towards intelligence and high-endization, fiber laser marking technology is constantly evolving. The integration of Industry 4.0 technologies enables seamless connection between marking systems and production management platforms, realizing real-time data interaction and quality monitoring . Customized solutions for different production scenarios, such as variable-speed production lines and special material cables, further expand the application scope of fiber laser marking machines.

In conclusion, fiber laser marking machines have brought a paradigm shift to the cable and wire industry with their permanent marking, high efficiency, environmental protection and versatility. They not only meet the strict requirements of modern manufacturing for product identification but also provide strong technical support for the high-quality development of the cable industry. With continuous technological innovation, fiber laser marking technology will play an even more important role in the future, promoting the industry towards higher precision and intelligence.