Why DOD Printers Excel in Large-Character Industrial Marking

Core Advantages: Precision, Speed, and Non-Contact Operation on Hot, Rough, or Moving Surfaces

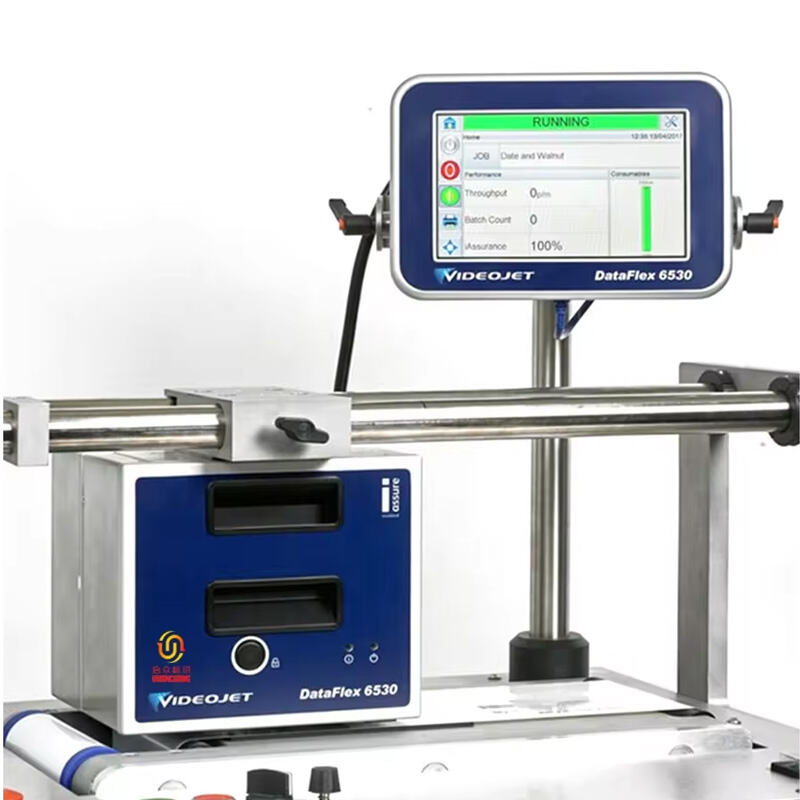

The Drop-on-Demand (DOD) tech really stands out when it comes to marking in industrial settings. These piezoelectric printheads shoot out tiny ink droplets with incredible precision, which means we get clear, easy to read marks at least 12mm tall, even if the surface isn't perfectly flat or stable. One big plus is that since there's no actual contact between the printer and what's being marked, it works great on materials heated up to around 600 degrees Celsius without messing up the surface or causing heat related problems. Factories can keep running smoothly too because these printers go at speeds over 120 meters per minute. What makes DOD so valuable? Well, first off, there's basically no downtime while operations run continuously. Second, the quality stays consistent even when conveyor belts aren't moving perfectly straight. And finally, unlike older methods that physically touch the material, DOD completely avoids issues like parts wearing down or changing shape from repeated contact.

Material Versatility: Reliable Adhesion on Steel, Aluminum, Cast Iron, and Oxidized Metals

DOD printers tackle those stubborn adhesion issues thanks to specially formulated ink chemistry. The rich pigment content actually forms chemical bonds with metal surfaces instead of just sticking to them, which gives the printed marks excellent resistance against wear and tear plus stays stable even when exposed to harsh environments over time. These printers work wonders on tough materials where regular marking methods fail completely. Think about oxidized surfaces covered in oil or rust, the rough porous cast iron found inside heavy machinery parts, or the slick anodized aluminum commonly seen in aircraft components. Industry tests have shown something pretty impressive too: after going through intense chemical cleaning processes, these inks still maintain around 99% readability. That kind of durability makes them perfect for places where clear identification is absolutely critical, such as busy steel production plants or sensitive defense manufacturing operations.

Meeting Defense & Heavy Industry Compliance with DOD Printers

DFARS 252.211-7003 and MIL-STD-130 UID Requirements for Permanent, Machine-Readable Marking

The defense industry faces strict traceability rules from regulations like DFARS 252.211-7003 and MIL-STD-130. These rules demand permanent UID markings that can last through years of harsh conditions in the field. DOD printers handle this challenge by putting durable ID marks right on components even when they're hot, rough surfaced, or constantly moving around during production. This approach cuts out extra steps like traditional etching methods or applying labels later. The printers use advanced piezo printheads to create those tiny but readable 2D Data Matrix codes with incredible detail at 5 mil resolution. Military tests show these codes stay intact for over two decades on tough materials including titanium parts, chrome plated steel, and various heat treated metals. For defense suppliers, this means assets remain trackable throughout their entire lifecycle no matter where they end up in the supply network.

ISO/IEC 15415 Validated Legibility for 12 mm Characters in Harsh Logistics Environments

The global logistics industry needs markings that stay readable both by machines and humans even when exposed to harsh environments. Think salt corrosion from ocean air, intense desert sunlight, or constant physical shocks. The ISO/IEC 15415 standard basically checks if those 12mm letters and numbers can still be read clearly after going through all sorts of tough tests. These include things like being sprayed with saltwater, submerged in hydraulic fluids, and dropped repeatedly to simulate real world impacts. Top military spec printers get their Grade A rating because they use special inks that actually form chemical bonds with metal surfaces at a molecular level. This works particularly well on metals that have been oxidized or are naturally porous. Lab tests accelerated aging processes show around 98% visibility remains after about 1,000 hours of exposure. That means scanners keep working properly in busy port areas, rail yards, and remote military locations where nobody has time to manually check every single tag.

Real-World DOD Printer Deployment: Performance, Integration, and ROI

Case Study: Nucor's Cast House – Billet Traceability at 120+ ppm with Zero Downtime

In the casting area at Nucor, those DOD printers made tracking every single billet possible by stamping marks on about 120 components each minute right there on the moving 600 degree Celsius billets, all without messing up the production speed or needing anyone to move things around. Traditional contact marking systems just couldn't handle this kind of work. The new non-contact DOD approach stopped those annoying alignment problems and unexpected machine stops completely. After running tests in actual industrial settings, they saw roughly 18 percent less wasted materials and absolutely no downtime caused by marking operations. The return on investment came pretty quickly too, hitting full value within just eight months thanks to better line efficiency and much less time spent dealing with scrap material.

Thermal & Chemical Resilience: DOD Inks Surviving 600°C Radiant Heat and Mill Coolants

DOD inks are engineered for the most punishing industrial settings–bonding instantly to hot metals during forging and resisting degradation from alkaline coolants, solvents, and abrasive handling. Third-party testing verifies sustained legibility after:

- 15-second exposure to 600°C radiant heat

- Immersion in pH 10+ industrial solvents

- Continuous abrasion from high-speed conveyor contact

This resilience ensures markings remain compliant with both MIL-STD-130 and ISO/IEC 15415–even after downstream processing such as heat treatment, painting, or passivation–making DOD the only marking technology validated across the full lifecycle of defense and heavy-industry components.

FAQ

What is Drop-on-Demand (DOD) technology?

DOD technology involves piezoelectric printheads that expel tiny droplets of ink with precision, enabling high-quality marking suitable for various industrial conditions.

Why is DOD preferred over traditional marking methods?

DOD is non-contact, reducing wear and avoiding alignment issues. It provides high speed and sharp marks even on hot or difficult surfaces.

How do DOD printers comply with defense industry standards?

DOD printers provide permanent, machine-readable ID marks adhering to standards like DFARS 252.211-7003 and MIL-STD-130.

Can DOD printers mark on challenging materials?

Yes, DOD printers can effectively mark on materials such as oxidized metals, cast iron, and anodized aluminum due to their special ink chemistry forming chemical bonds.